We recommend that spices from different lots or dif-ferent suppliers be compared in a manner that is as standardized and objective as possible.

In general this evaluation would involve a number of people comparing ‘blind’ (i.e.: coded) samples using identical methods. Preferably, their observations should be recorded on a numerical scale.

Sample Preparation

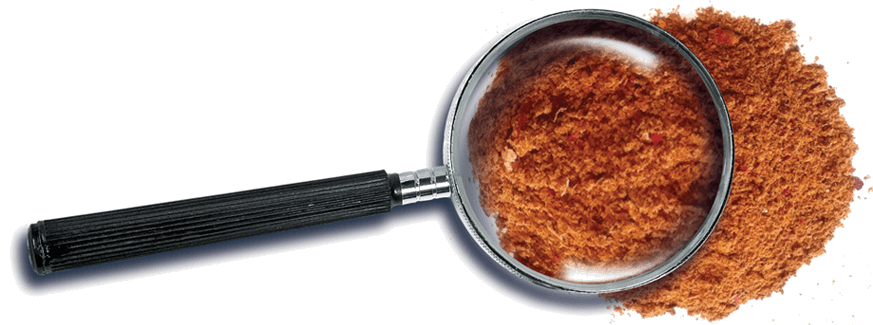

- On white paper, spread out a thin layer of each spice. Samples of the spices to be compared should be next to each other.

- In a clear beaker prepare a ‘tea’ or flavor extract of each sample by dispersing 1% spice in water. Heat to 140ºF to 150ºF. Allow to steep for 5

minutes. Cool to room temperature.

Appearance and Color

We recommend that visual inspections – particularly those performed to evaluate color — be carried out under bright, daylight-spectrum lighting.

- Dry Spice: Evaluate for conformity to product specifications, extraneous material, average particle size, range of sizes, color uniformity, intensity and hue.

- 1% Dispersion: After settling, compare color of liquid and depth of “solids” below.

Aroma

Allow a minimum of thirty seconds of recovery time between each aroma evaluation.

- Dry Spice and 1% Dispersion: An aroma characteristic of the spice is desired. “Off” odors are problematic and should be investigated.

Flavor and Texture

- Dry Spice: Place sample on front of tongue. Note flavor release. Gently chew spice sample for a few seconds. Note texture and flavor profile.

- 1% Dispersion: Transfer some liquid to a teaspoon. Sip liquid into mouth. Allow it to reside in the mouth for at least 10 seconds. The sample may be swallowed or spit out. Describe or numerically score the flavor profile against the ideal flavor characteristics of that particular spice. Clean, strong flavors are desired. “Off” flavors are problematic.